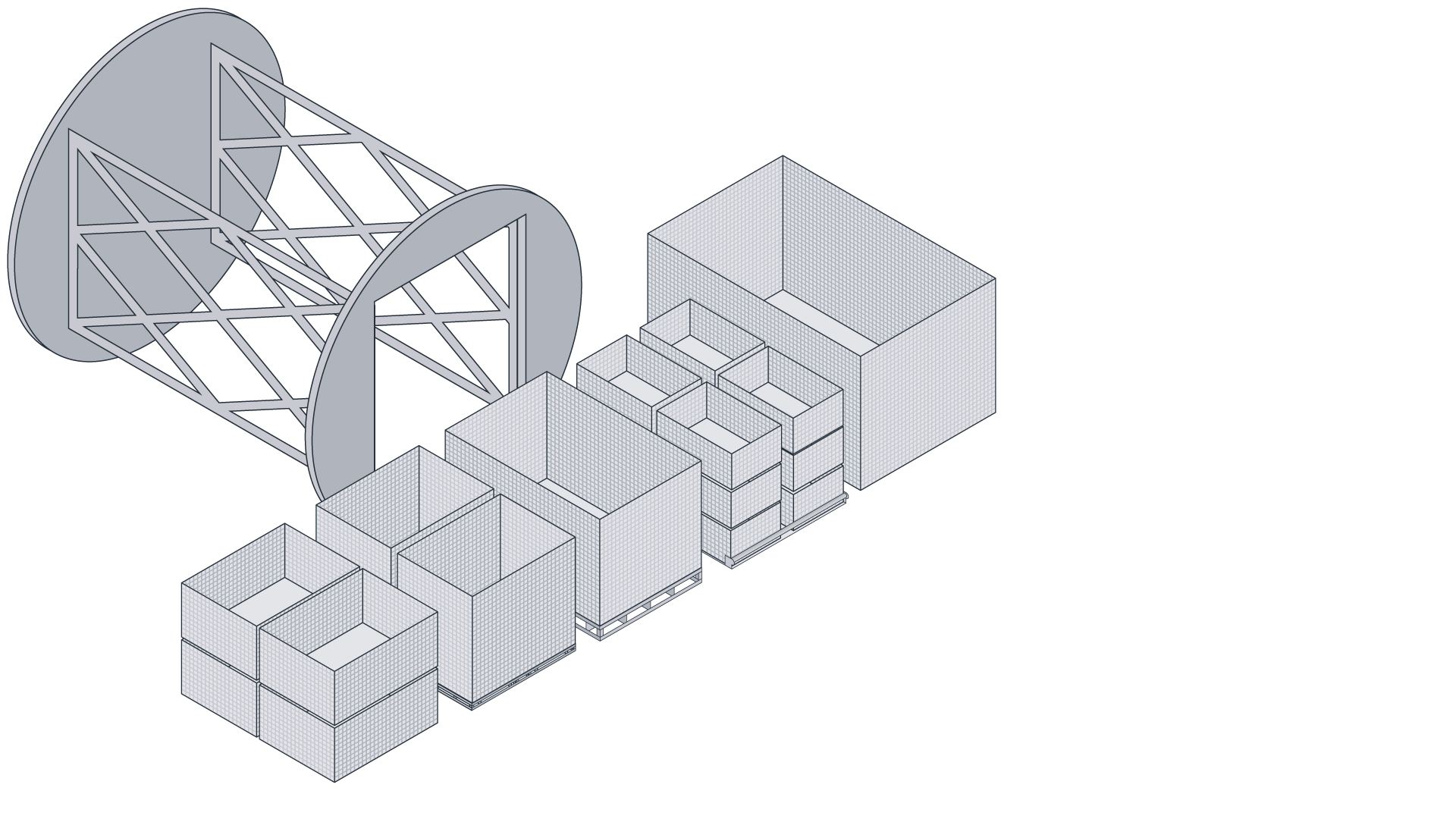

PERO R4

Hardly ordered – almost at your place!

The modular prefabricated PERO R4 for your specific application is available at short notice.

For your personal consultation, please contact our sales team at:

+49 (0)8231 6011-884

or send us an e-mail to: pero.vertrieb@pero.ag

We will gladly call you back.

Cleaning with solvents

Cleaning with solvents