Cleaning tests & reports

At the PERO Centre of Competence

The productivity of a manufacturing plant is determined by the availability of the cleaning technology.

In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology.

At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Cleaning tests

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts.

Great service and support

- Cleaning tests free of charge, using your own parts; including documentation

- Evaluation of cleanliness analyses

- Gaining new insights into own cleaning processes

Machine park for testing and cleaning options

At our Centre of Competence measuring 1,100 square metres, there are more than 15 testing units at your disposal for the optimisation of your cleaning processes.

Wet cleaning methods using aqueous media or solvents

- Batch units for parts carriers up to 660 x 480 x 300 mm in size

- Tunnel cleaning unit

- Cleaning units for large parts up to approx. 2,100 mm in width and 1,500 kg in weight

- Test and compare various media and alternative cleaning processes

- Get to know efficient parts handling methods and equipment

Laboratory for technical cleanliness

At the PERO laboratory for technical cleanliness that forms part of our Centre of Competence, we analyse and assess the outcomes of the cleaning tests.

- Analytical lab, vacuum drying unit, testing instruments

- Examination under light microscope

- Assessment of cleanliness analyses according to VDA 19 and other standards

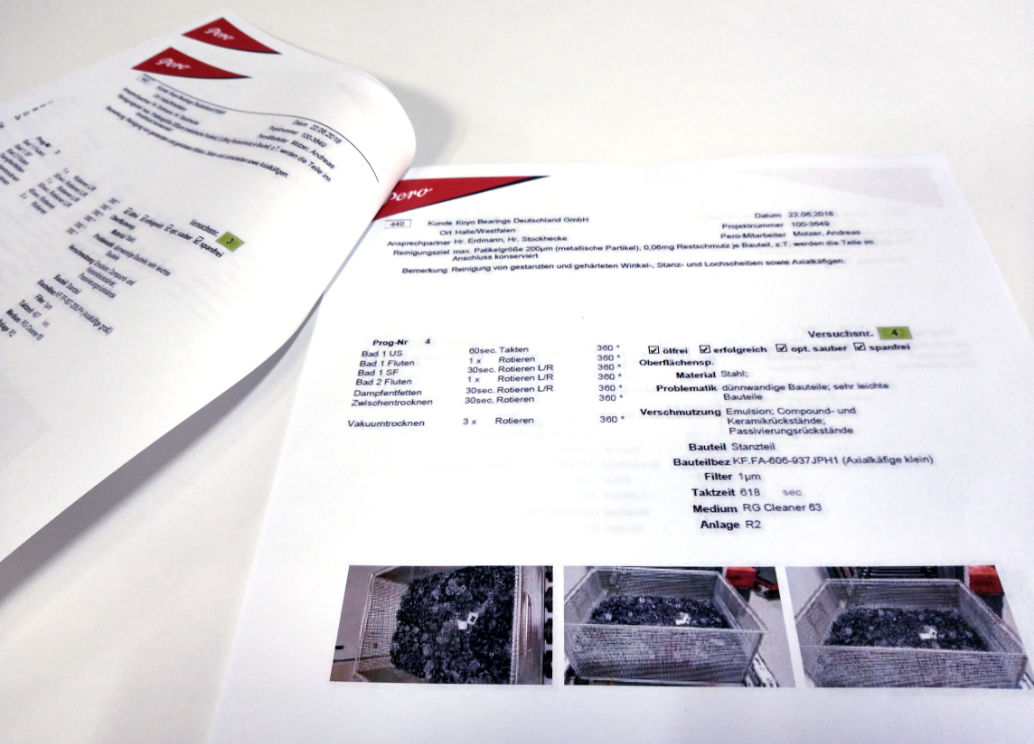

Documentation

The cleaning report lists the cleaning methods and results of the tests. The chosen cleaning medium and process steps are described and documented in detail.

Cleaning reports provide all the data you need for project decisions within your company!

Process-Safety

By documenting the required technical cleanliness and the processes of your chosen method, you obtain an unrivalled level of process safety at an early stage.

You know that you will achieve the necessary technical cleanliness long before you integrate the cleaning unit into your production plant.

This means that you can assess the commercial viability of your future processes in advance.