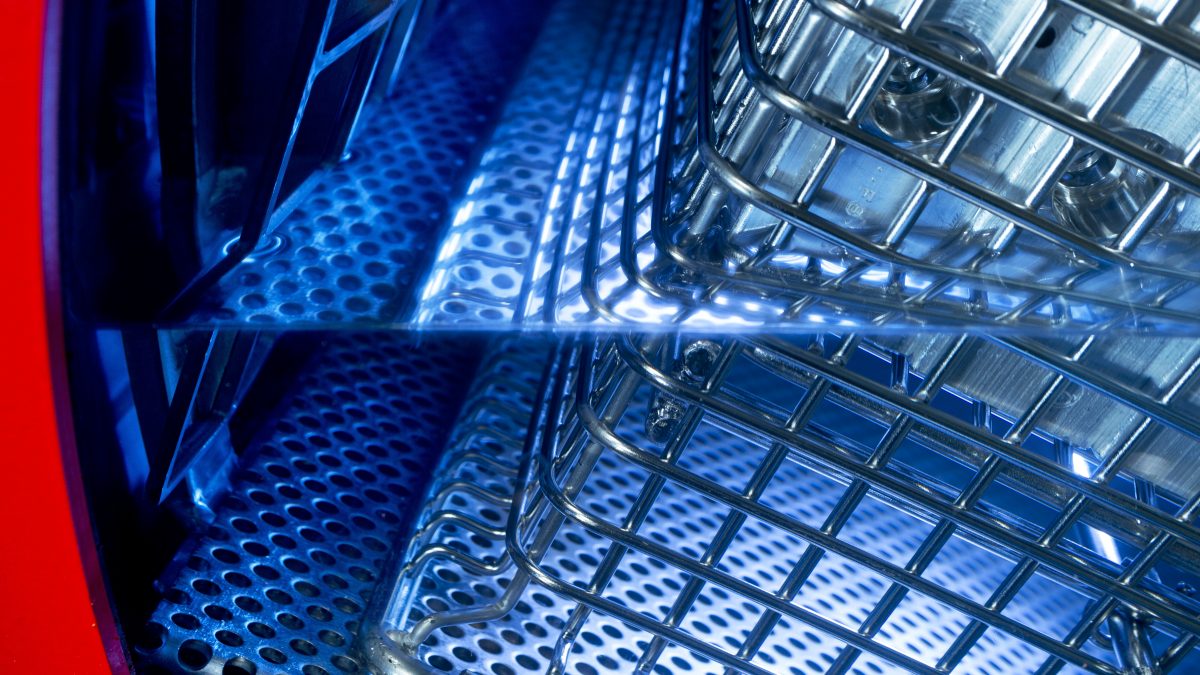

Perfect cleaning after machining

Industrial parts cleaning

Visit us at the METAV 2022 - H16 E05

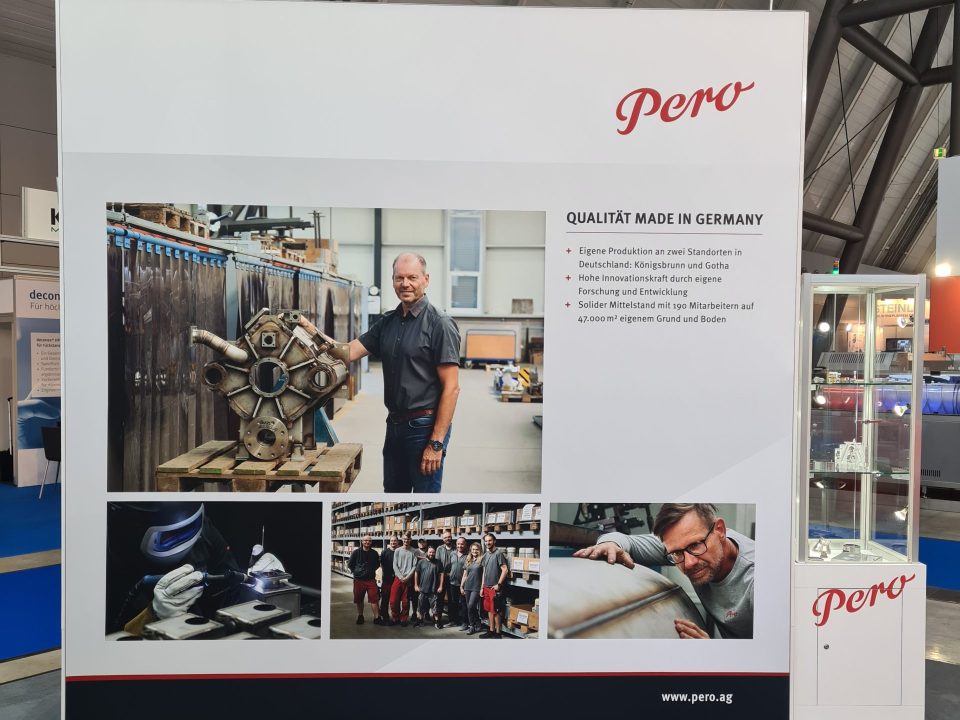

Anyone who machines or forms components often has to remove chips, grease and other contaminants from them between the individual machining steps and before assembly. High-quality cleaning systems, such as those we manufacture in Königsbrunn, are crucial for this. Interested parties and trade visitors to the Metav 2022 trade show can experience how reliable, fast and cost-efficient cleaning works using our compact Pero S1A as an example in Hall 16, Booth E05.

From June 21 to 24, the Düsseldorf trade show will focus on the broad spectrum of metalworking. This includes not only machining and forming. The cleaning of components also plays an important role. For Pero's systems, it doesn't matter what chips, grease, oil or dust have to be removed, what material the components are made of or what their geometry is. We have a suitable solution for every cleaning task in industrial use.

The decisive factor here is the modular design of the systems, which operate on the basis of solvents or aqueous media and can be individually adapted to the needs of the application. The high level of expertise of our employees and the Pero Competence Center are important here. Here, on request, experts also test the cleaning of the potential customer's original parts and demonstrate the advantages and disadvantages of the individual processes and technologies.

In Düsseldorf, we will also demonstrate that entry into high-quality solvent cleaning does not necessarily have to be expensive. The S1A on display is already available from an upper five-digit euro amount and is particularly suitable for small to medium-sized series. Through mechanical rotation, swiveling, flooding and surge flooding, the system rinses off all contaminants so that the components leave the system clean and grease-free. Operation under full vacuum protects the cleaning medium, minimizes solvent consumption, reduces energy consumption and enables short cycle times.

#peroag #b4b #machineconstruction #madeingermany #cleaningtechnology #partscleaning #familybusiness #leadership #tradefair